Tool Making and Moulding

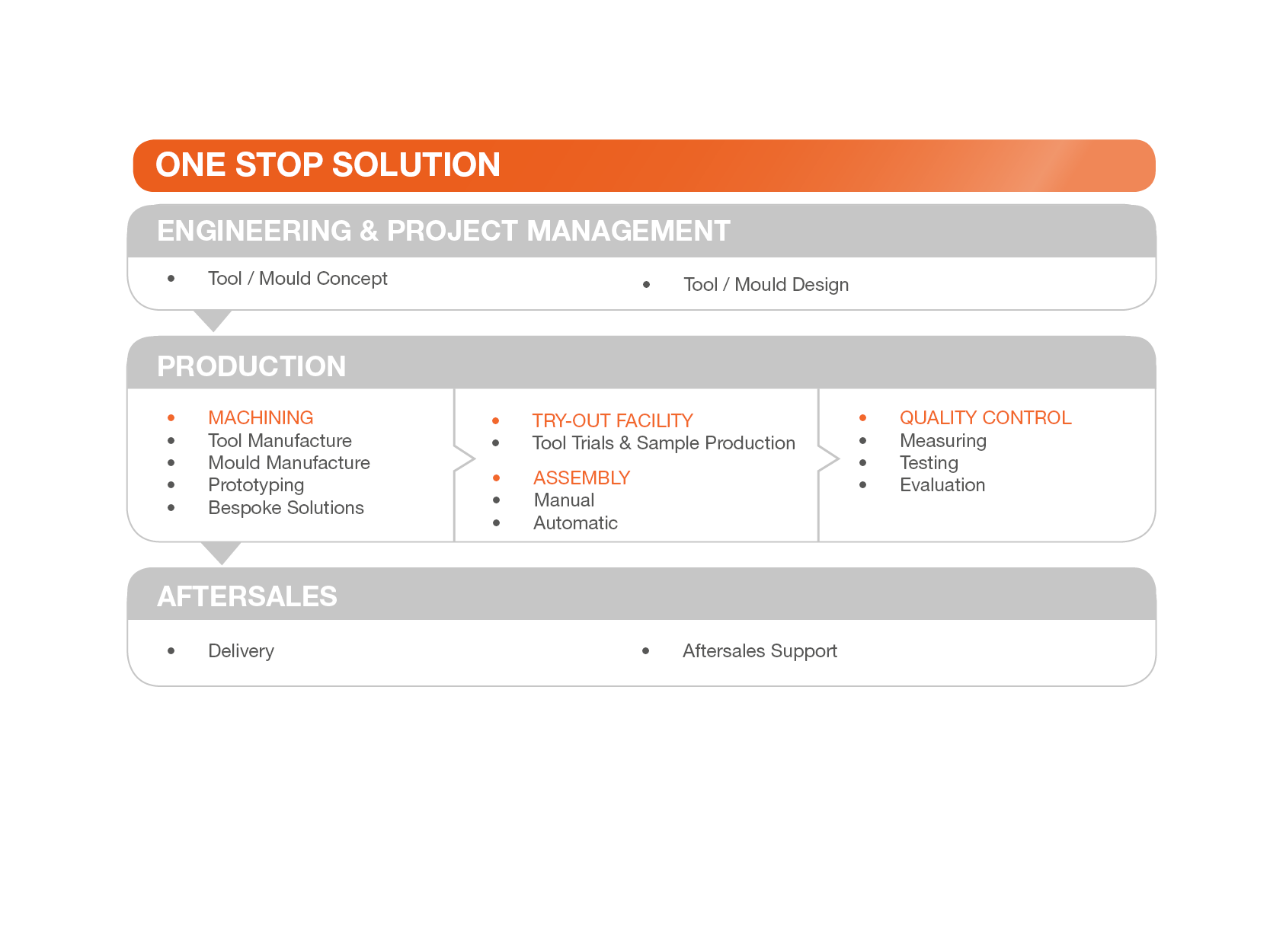

We constantly strive to develop new innovative solutions which push the boundaries of press tool and mould design. The benefits this provides for our customers are the reasons they have remained loyal to us for over 50 years.

We are one of the leading designers and manufacturers of press tools, injection moulds, jigs and fixtures within the UK.

Providing bespoke tooling solutions to many of the world’s leading manufacturers and first-tier suppliers within the automotive, aerospace, white goods, pharmaceutical and medical industries.

Tool Concept

Our relationship with the customer very often begins at the concept stage of a new

project. With ever increasing pressure on tooling budgets to deliver “more for less”

we find that involving us at this stage can be extremely beneficial to the customer.

Being involved in the initial discussions of the design of the product, we can help

highlight any areas that could potentially create issues in manufacture. Drawing upon

our 40 years’ experience in both press and mould toolmaking we can also suggest

ideas in order to improve and streamline proposed production routes resulting in

more cost effective and innovative tooling.

Tool Design

Solidworks & Cimatron software is used in our toolmaking division for all elements of

the tool design process. From generating 3D solid models, to producing all drawings

for parts and assembly, BOM lists for materials ordering, and CAM programming for

CNC manufacture. Fully detailed drawings and 2D/3D CAD data are provided as

standard with all tools produced.

Moldex 3D software enables us to analyse all aspects of the injection moulding process, providing you with a full understanding of fill, pack, cool, warp of parts before we start tool design. This means we understand the very best processing window to optimise profitability from the tool.

Tool Manufacture

Our state-of-the-art production facilities offer our customers a variety of manufacturing disciplines on ultra-accurate, highly efficient machining centres. We are able to provide

a full range of machining capabilities including CNC milling (3 & 5-axis), CNC turning

(mill/turn), Wire EDM, EDM sink, Grinding (surface and cylindrical), and once started on a tool we will see it through to completion, including press trials, inspection, validation, FAT’s, tool sign-off and on-site support.

Mould Manufacture

We have extensive knowledge and experience in the design, development, and

manufacture of high quality mould solutions and offer the manufacture of:

Medical moulds

Multi-shot moulds

Multi-cavity moulds

Prototype moulds

Individual bespoke solutions

Plastic Hot Air Stake Assembly

The PHASA process uses non-contact hot air and cold tool for forming a rivet type

fixture commonly known as staking and making for a repeatable and very capable

process. PHASA undertakes plastic assembly projects primarily within the automotive sector supplying world wide to most Tier 1 and Tier 2 companies.

PHASA machines are used for the assembly of interiors, exterior and electronic parts,

offering a robust and cost effective plastic joining heatstaking alternative to contact hot tool, ultrasonic and Impulse staking.

Other Services

Did you know? We also provide an extensive range of other manufacturing services, including:

- Precision Engineering

– CNC Milling 3/4/5 Axis

– Automated Lights Out Production

– CNC Turning

– Deep Hole Drilling

– Grinding

– Wire EDM

– Assembly

- Electronic Manufacture

– Automation; SMT, Axial & Radial through-hole components

– AOI

– Procurement

– Cable, Looms & Harnesses

– Box, panel & cabinet build

- Sheet Metal Fabrication

– Laser cutting & punching

– Bending & forming

– Metal pressings

– Robot Mig/Tig Welding

-Powder Coating

– Wet painting

– Sulphuric anodising

– Surface Treatments

There exists a intense approach for selecting free lance authors to participate in our companycheap reliable essay writing service in 3 hoursand ultizing our guidance there is a good quality ensure, excellent composing rate, secrecy and continual customer care.