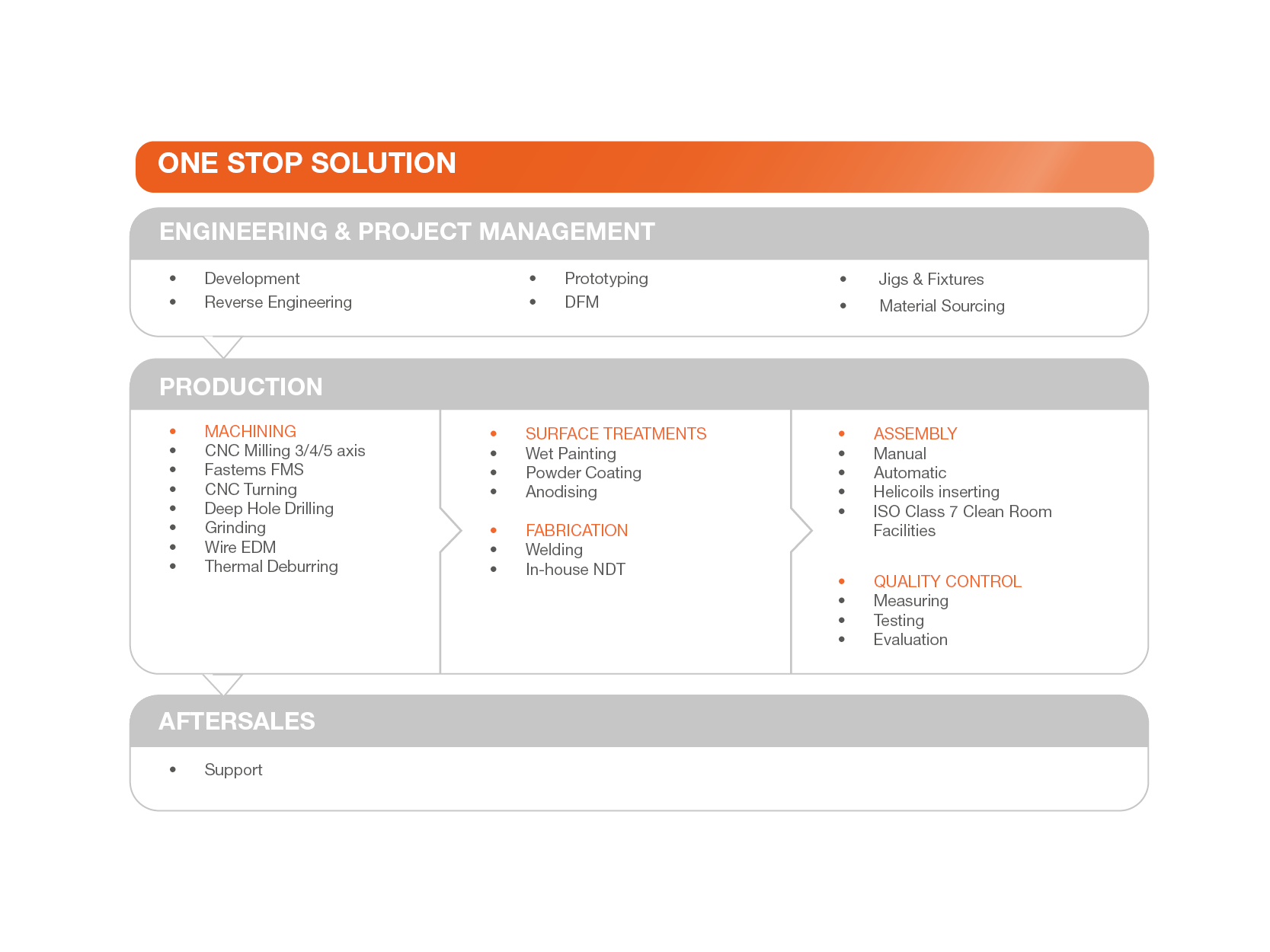

Precision Engineering

Across our sites our agile manufacturing processes offer the flexibility your products

deserve. Delivering a wide range of custom manufactured components, including

complete turn-key solutions.

CNC Milling 3/4/5 Axis

Offering 3, 4 and 5 axis vertical and horizontal milling. We can produce components utilising the most accurate and cost effective methods. 5 axis technology is ideal for your more complex requirements providing repeatable accuracy for your parts.

Automated Lights Out Production

Incorporating multiple horizontal milling machines working fully independently with Fastems FMS Systems. We are able to optimise your production through automated raw material loading and ready part unloading with a robot. This means stable quality and longer unmanned production periods.

CNC Turning

Incorporating multiple horizontal milling machines working fully independently with Fastems FMS Systems. We are able to optimise your production through automated raw material loading and ready part unloading with a robot. This means stable quality and longer unmanned production periods.

Deep Hole Drilling

We are specialists in the complete manufacture of fully machined and deep bored components. We supply a wide variety of industries including aerospace, oil and gas and the medical sector.

Grinding

We can offer cylindrical and horizontal surface grinding with the capability to grind high-accuracy components to your bespoke requirements.

Wire EDM

Substantial investments over the years has been made to ensure we have a state of the art EDM facility. This is helping us provide an even faster turnaround service on complex geometries for our customer base.

This capability make us a key partner for demanding industries and diverse applications producing end user products for a global marketplace.

Our internal expertise in conjunction with a unique machine partner network ensure that speed, accuracy and quality are always a given for our customers.

Thermal Deburring

We provide the capability to manufacture and thermal debur manifolds to a high quality standard delivered to customer ready for assembly.

The Benefits include:

- No loose burrs

- In-house

- Improved delivery times

- Lower costs

- High Quality

Assembly

We offer manual / auto assembly and test of electro-mechanical components and sub-assemblies in a clean and controlled environment to ISO Class 7.

Other Services

Did you know? We also provide an extensive range of other manufacturing services, including:

- Tools, Moulds & Fixtures

– Tool manufacture

– Mould manufacture

– Prototyping

– Bespoke solutions

– Tool Trials & sample production

– Automatic / Manual Assembly

– Measuring, Testing, Evaluation

- Electronic Manufacture

– Automation; SMT, Axial & Radial through-hole components

– AOI

– Procurement

– Cable, Looms & Harnesses

– Box, panel & cabinet build

- Sheet Metal Fabrication

– Laser cutting & punching

– Bending & forming

– Metal pressings

– Robot Mig/Tig Welding

-Powder Coating

– Wet painting

– Sulphuric anodising

– Surface Treatments